Unleash the Power of Print: Promotional Product Printing Methods Guide

In this post, we discuss the various printing methods that are available here in our online shop. Not only will we discuss what each method is, but we will also describe which products work best for which method. Read through to the bottom to get some of your FAQs answered as well. Happy printing!

When it comes to promotional products, the power of printing and branding is undeniable. From company logos on pens to vibrant designs on T-shirts, the right printing method can transform an ordinary item into a memorable promotional giveaway or tool. In this blog, we'll explore some of the most popular printing techniques used in the world of promotional products, demystifying the process and helping you make informed choices for your brand. Make an impact with your products by choosing the right printing method for the perfect item.

Screen Printing:

Let's kick things off with a classic: screen printing. This technique involves using a mesh screen to transfer ink onto a surface. It's ideal for large quantities and designs with bold, solid colors. Screen printing offers excellent durability, ensuring your design withstands regular use and washing. From T-shirts and tote bags to promotional banners, screen printing continues to be a go-to choice for many marketers. In most cases, it doesn’t matter which type of material you use, as it can be applied to almost any flat surface.

Ideal for: T-shirts or any other apparel item

Similar to: Pad printing

Digital Printing:

In the fast-paced world of promotional products, flexibility and speed are crucial. Enter digital printing, a technique that allows for high-resolution designs to be directly printed onto various surfaces or materials. With digital printing, or as it is sometimes called direct digital printing (DDP) and computer-to print, you can unleash your creativity without compromising on quality. It's perfect for small print runs, promotional items, and intricate designs that demand vibrant colors and fine details. Plus, its quick turnaround time makes it a popular choice for time-sensitive projects. Since the design comes from the computer, you are not as limited in terms of amount of products needed or time.

Ideal for: Any smooth surface, like paper notebooks or sticky notes

Similar to: Offset printing

Sublimation:

For eye-catching, full-color designs on textiles, sublimation is the way to go. This process involves printing designs onto a special transfer paper and then applying heat to transfer the ink onto the fabric. Sublimation is particularly effective on polyester materials, as the ink permeates the fibers, resulting in vibrant, long-lasting prints. From custom apparel and sports jerseys to mugs and mouse pads, sublimation offers endless possibilities for promotional products that make a statement.

Ideal for: Lanyards

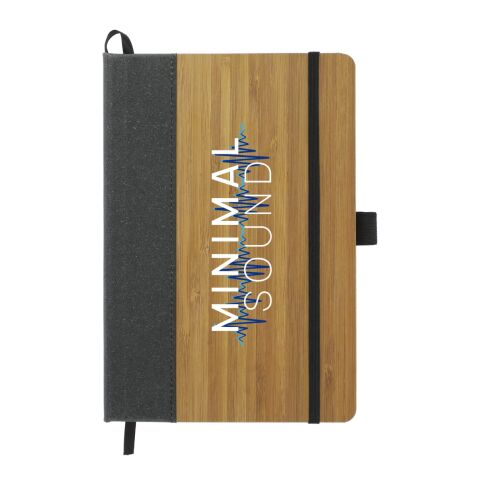

Laser Engraving:

If you're aiming for a touch of elegance and longevity in your promotional products, laser engraving is a superb choice. This method uses a laser to etch designs onto various materials, such as metal, wood, and glass. The precision and permanence of laser engraving make it perfect for promotional giveaways or corporate gifts, corporate awards, and high-end promotional items. From engraved keychains and pens to sleek metal water bottles, laser-engraved products exude sophistication and style.

Ideal for: Products made from metal like USB flash drives or wood like cutting boards

Offset Printing:

When it comes to printing high-quality images and complex designs on paper, offset printing reigns supreme. This technique involves transferring ink from a plate to a rubber blanket and then onto the printing surface. Offset printing offers exceptional color accuracy, sharpness, and consistency, making it an excellent choice for brochures, flyers, catalogs, and other printed materials. Its versatility, combined with the ability to produce large quantities efficiently, makes offset printing a staple in the world of promotional products.

Ideal for: Paper printed products such as flyers, catalogs or brochures

Pad Printing:

For imprinting logos and designs on small and irregularly shaped items, pad printing comes to the rescue. This method uses a silicone pad to transfer ink from an engraved plate onto the object's surface. Pad printing is perfect for items like pens, stress balls, and USB drives, as it can accommodate curved or uneven surfaces with ease. Its ability to create fine details and vibrant colors makes pad printing a reliable choice for creating memorable promotional products. It is classified as flat printing, making it similar to screen printing.

Ideal for: Round surfaces such as stress balls or pens

Similar to: Screen printing

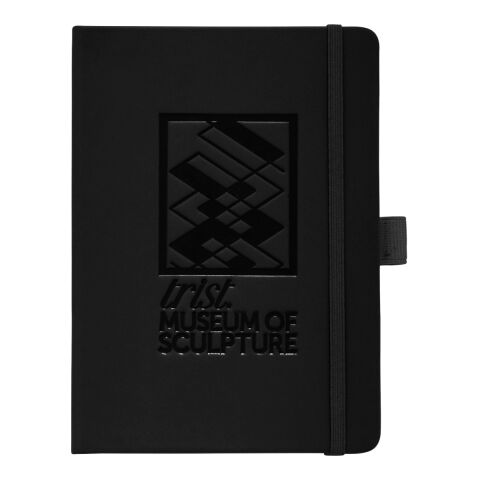

Relief Printing:

With a history that dates back centuries, relief printing remains an artful technique for promotional products. This method involves carving a design into a block or plate, applying ink to the raised surface, and then pressing it onto paper or fabric. Relief printing creates a distinctive, textured look that adds depth and character to your promotional items. From business cards and postcards to fabric banners and posters, relief printing brings a touch of tradition and craftsmanship to your brand.

Ideal for: Business cards

Transfer Printing:

Lastly, let's explore transfer printing, a versatile technique that enables designs to be transferred onto a wide range of materials. This method involves printing the design onto transfer paper and then applying heat or pressure to transfer it onto the item. Transfer printing allows for vibrant, full-color designs and offers flexibility in terms of materials. It's commonly used for textiles, ceramics, and promotional products like mugs, T-shirts, and caps, allowing you to create visually striking items that grab attention.

Ideal for: Hats & caps, apparel, mugs, etc.

Similar to: Sublimation

FAQs

You have now learned some of the basic printing methods and which products they are best suited for, however, you might still have some questions about the overall printing process. Here are some of the most frequently asked questions when it comes to the printing methods of promotional products.

Screen Printing vs. Sublimation

Screen printing and sublimation are two popular methods for printing designs on various surfaces. Screen printing involves creating a stencil, known as a screen, by blocking out areas that don't need ink. The screen is then placed on the material, and ink is forced through it using a squeegee. This process allows for vibrant and durable prints, making it ideal for large quantities and designs with solid colors.

Benefits:

- Mass production

- Solid color designs

- Allows for bright and colorful designs

On the other hand, sublimation is a digital printing method that uses heat to transfer ink onto the material. The design is first printed on special transfer paper with sublimation ink, and then heat and pressure are applied, causing the ink to turn into a gas and penetrate the material's fibers. Sublimation offers vivid, high-resolution prints with the ability to reproduce intricate details, gradients, and even photographs. It works best on synthetic materials, such as polyester or products like lanyards, where the ink can bond effectively.

Benefits:

- Ability to reproduce high-resolution prints

- Ideal for detailed designs

- Works best on synthetic fabrics

In summary, screen printing excels in mass production and solid color designs, while sublimation is perfect for detailed and photographic prints on synthetic materials. Both techniques have their strengths and are widely used in various industries, including apparel, signage, and promotional items, to bring designs to life in their own unique ways.

Screen Printing vs. Digital Printing

As mentioned before, screen printing involves creating a stencil, or screen, where areas not requiring ink are blocked out. The screen is then placed on the material, and ink is pressed through it using a squeegee.

Benefits:

- Mass production

- Solid color designs

- Allows for bright and colorful designs

Digital printing, on the other hand, utilizes digital technology to directly transfer the design onto the material. It involves printing the design from a computer onto the material using specialized inkjet printers. Digital printing offers flexibility and the ability to reproduce intricate details, gradients, and even photographs with exceptional accuracy and resolution. This method is suitable for smaller quantities, branded items, and designs that require high levels of complexity.

Benefits:

- Digital technology

- Flexibility in reproducing complicated designs

- Ideal for smaller runs of promotional items

In essence, screen printing excels in mass production and solid color designs, providing long-lasting prints, while digital printing offers versatility, precise detailing, and the ability to create customized and complex designs with ease. Both techniques have their advantages and find applications in various industries, allowing for the creation of eye-catching and high-quality prints.

Best T-Shirt Printing Method

When it comes to printing designs on T-shirts, one of the best methods is undoubtedly screen printing. It's like the tried-and-true champ of custom promotional T-shirt printing! With screen printing, a stencil (or screen) is created, and ink is pushed through it onto the fabric, resulting in vibrant and long-lasting prints. For items that are frequently worn, this type of process is virtual for the artwork to last longer. The type of printing is also perfect for larger quantities and designs with solid colors, giving your desired T-shirts a professional and durable finish. This means, whether you want to hand out custom apparel during trade shows or to all your staff as onboarding gifts, you can do so with screen printing. Plus, this printing technique allows for precise registration and consistent results, making it a popular choice for apparel brands, events, and businesses looking to create high-quality, eye-catching T-shirts that their target audience will love to wear over and over again. Click here to understand the different methods of printing on T-shirts.

Whether you're aiming for durability, vibrancy, elegance, or versatility, the world of promotional product printing offers a diverse range of techniques to suit your brand's needs and desires. From the timeless appeal of screen printing and the flexibility of digital printing to the sophistication of laser engraving and the artistry of relief printing, each method brings its unique touch to your promotional items. By understanding the different printing methods available, you can make informed decisions and create promotional products that captivate and leave a lasting impression on your audience. Ensuring your logo or slogan lasts long after the event can often come down to the actual printing method. So, go forth, unleash the power of print, and watch your brand shine even brighter in the future! For even more information about all of these printing methods, be sure to read our full descriptions in the Glossary.